Manufacturing technologies

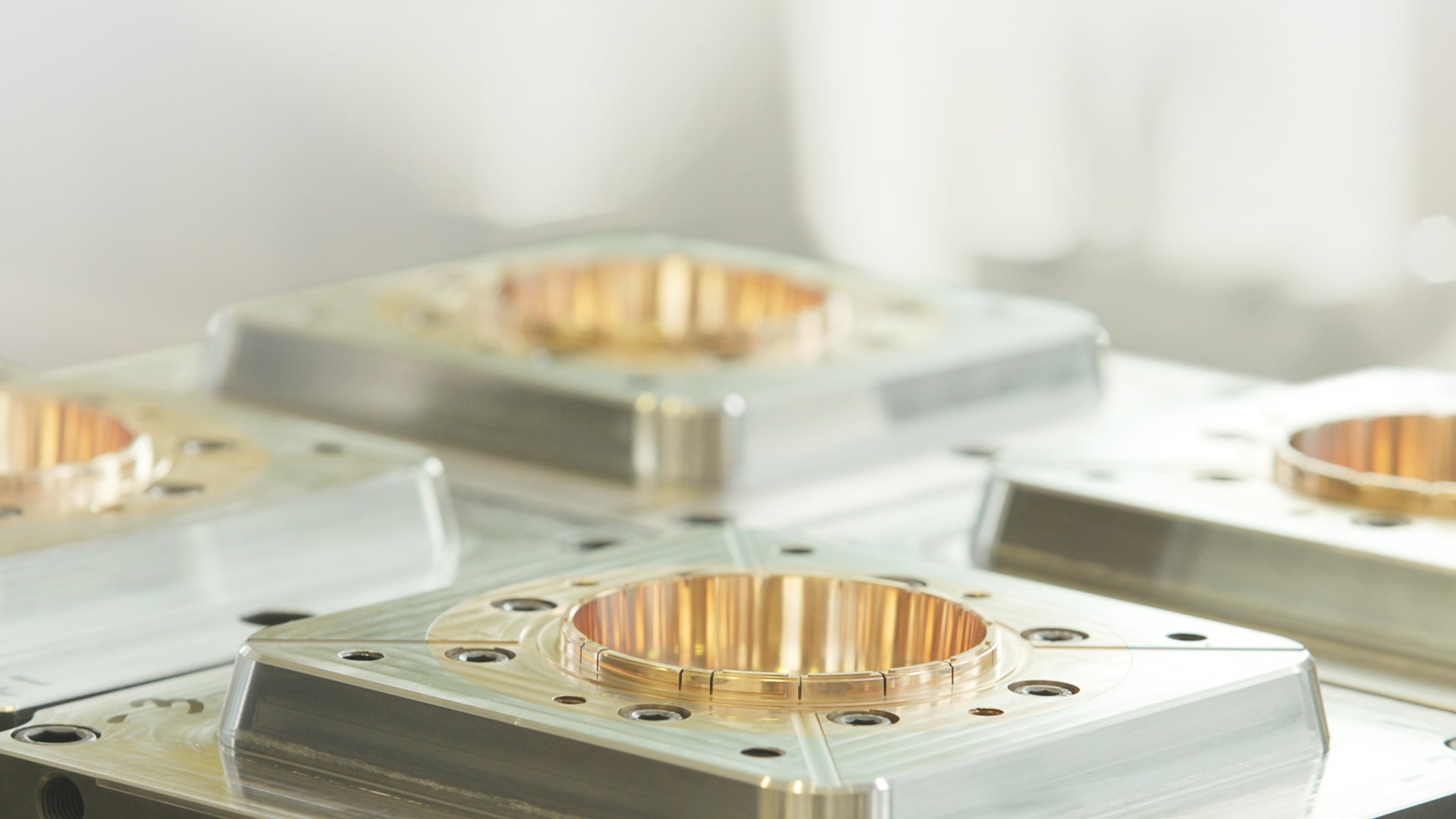

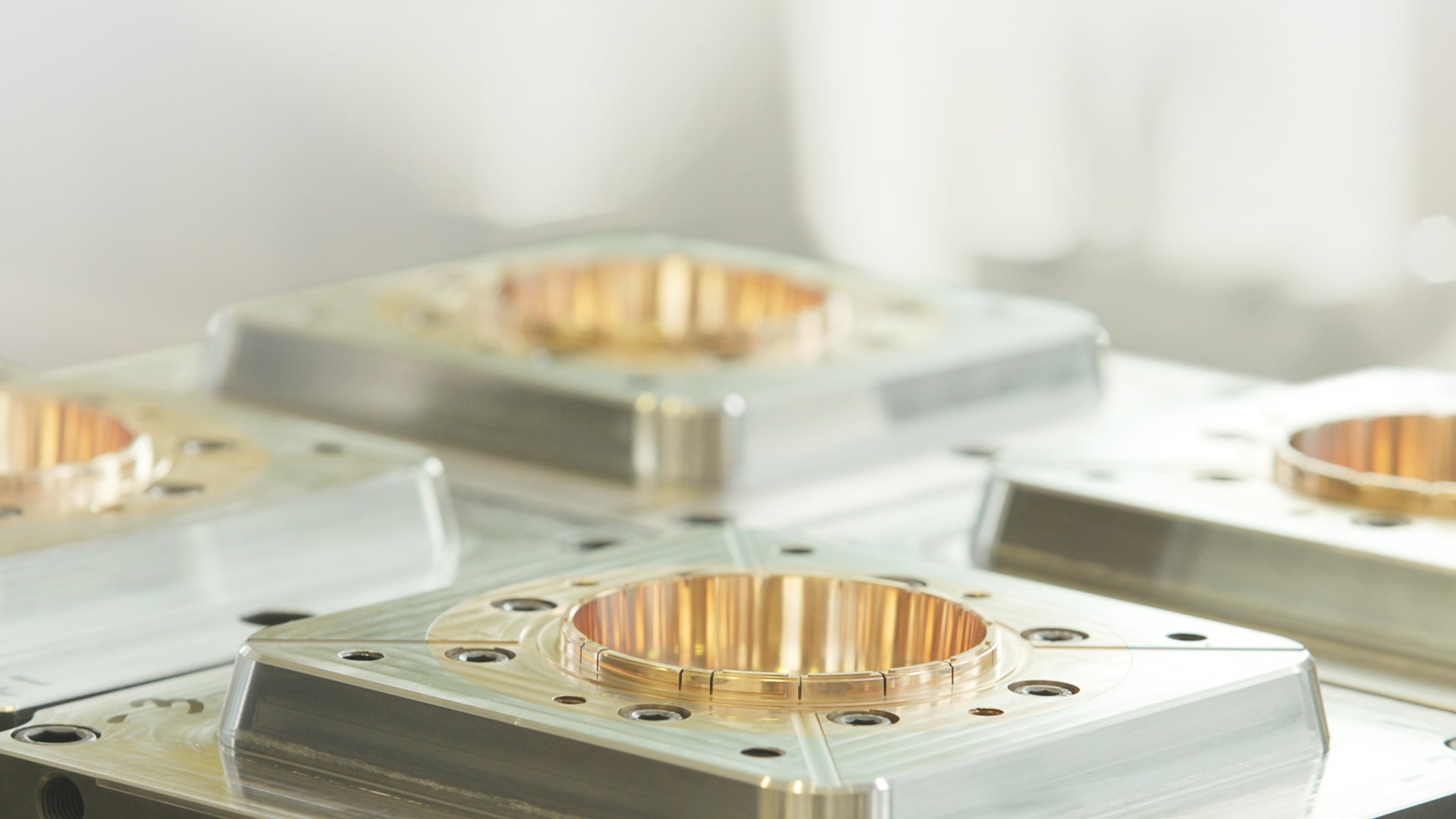

Tool room

Designing

- Using 3D modeling systems (CAD/CAM) lets us get difficult shaped parts

- Using 3D prototyping we can get vivid samples of a product

- Using computer-aided engineering guarantees us high accuracy of products we make

Molds production

- We have more than 20 items of metalworking equipment with CNC

Technical service and repairing of molding tools

- Using Laser metal deposition method helps us do repairs in short period of time

Injection molding

- Our modern fleet contains more than 98 injection molding machines of such brands as Engel, ВМB, Demag, Zhafir, Haitian

- Usage of robotized complexes minimizes human contact with ready products

- Systematic control with usage instruments with high level of accuracy provides flawless quality products output

Special technology

IML decoration

- The label is put in the injection molding tool in which the product is shaped, therefore bonding it permanently to the finished product

- This decoration method of firm plastic package is the most advanced one

Watch catalog

Sterilization capability

- It is the final stage in the production of single-use medical products

- The purpose of sterilization is to deactivate microbiological contamination on non-sterile products.

- Individual packaging of medical devices

Watch catalog

Embedded parts

- It helps get firm and affordable products

Pad printing

- This method let put pictures on ready product

Watch portfolio